Sustainability

We are committed to driving a more sustainable future for our industry.

Sustainability lies at the heart of our business, guiding the way we operate, innovate, and serve the growing community of customers who value making environmentally responsible choices.

Our collaboration with The Sustainability Hub marks the beginning of an ongoing journey of continuous improvement. Through a thorough evaluation of our products, business practices, processes, and supply chain, we are identifying both risks and opportunities to create meaningful, long-term impact.

Sustainability at Stonecut

We recognize the impact our industry can have on the environment and are committed to minimizing the harm caused by products and practices that damage it.

We act responsibly by reducing and recycling waste.

We engage customers to drive sustainability forward together.

We encourage sustainable choices with honesty and without greenwashing.

Stonecut is committed to continuous improvement across all areas of our business, integrating sustainable and environmental initiatives wherever possible.

We partner with The Sustainability Hub to provide customers with transparent, up-to-date product information, making comparisons easier and supporting informed decisions throughout the stone buying process.

The Sustainability Hub has worked closely with our team and supply chain to drive improvements in resource conservation, waste management, and to highlight stone options that reduce environmental impact and pollution.

We Offer 3 Types of Stone

Comparing Manufacturing Impacts

NATURAL STONE

Stone is quarried

Transported to producer

Cut into panels

Resin & Sealant applied

PORCELAIN SLABS

Clay, sand, feldspar and other minerals are mined

Raw materials transported to manufacturing plant

Ink, glaze and other additives are aquired/manufactured then transported to manufacturing plant

Ingredients combined with water, formed, dried and pressed. Images and glaze are applied, then fired

ENGINEERED STONE (MAN-MADE QUARTZ)

Raw quartz is mined

Quartz is crushed and sorted

Epoxy resin is manufactured. Acids, alchohols, styrene and peroxide are mixed to initiatea series of chemical reactions

Ingredients are transported to manufacturing plant

Quartz, resin and additives are combined, placed into molds compacted and cured

How We Evaluated Our Product

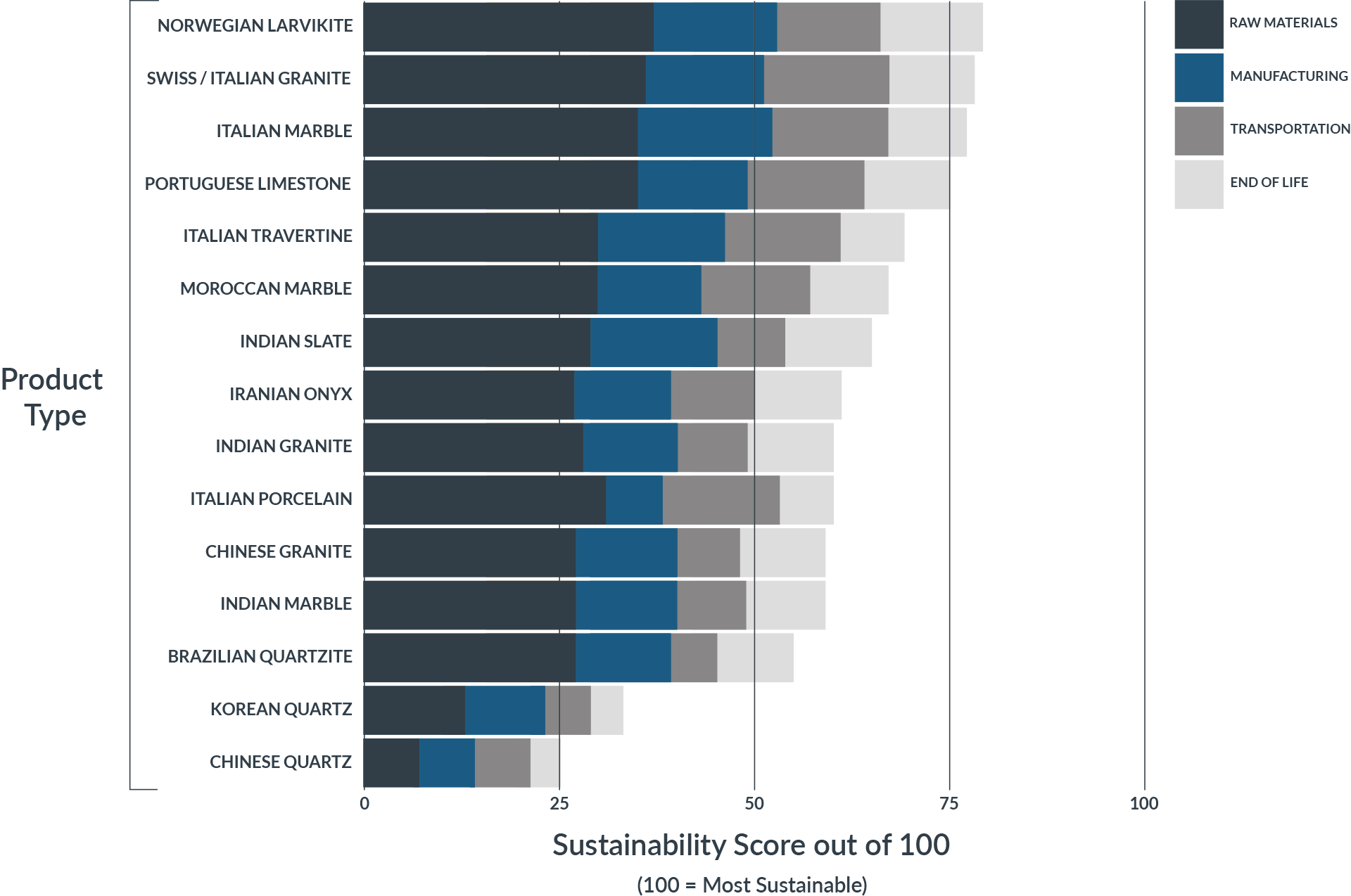

The Sustainability Hub conducted a full lifecycle analysis of our product range, rating each from most to least sustainable.

In developing this rating system, factors such as raw materials, manufacturing processes, transportation, and end-of-life impacts were carefully considered. While no recognized industry standards currently exist, this system is unique to Stonecut. We would welcome the introduction of such standards, but in the meantime, we feel it is our responsibility to provide this information as part of our commitment to customer service.

Product Sustainability Evaluation

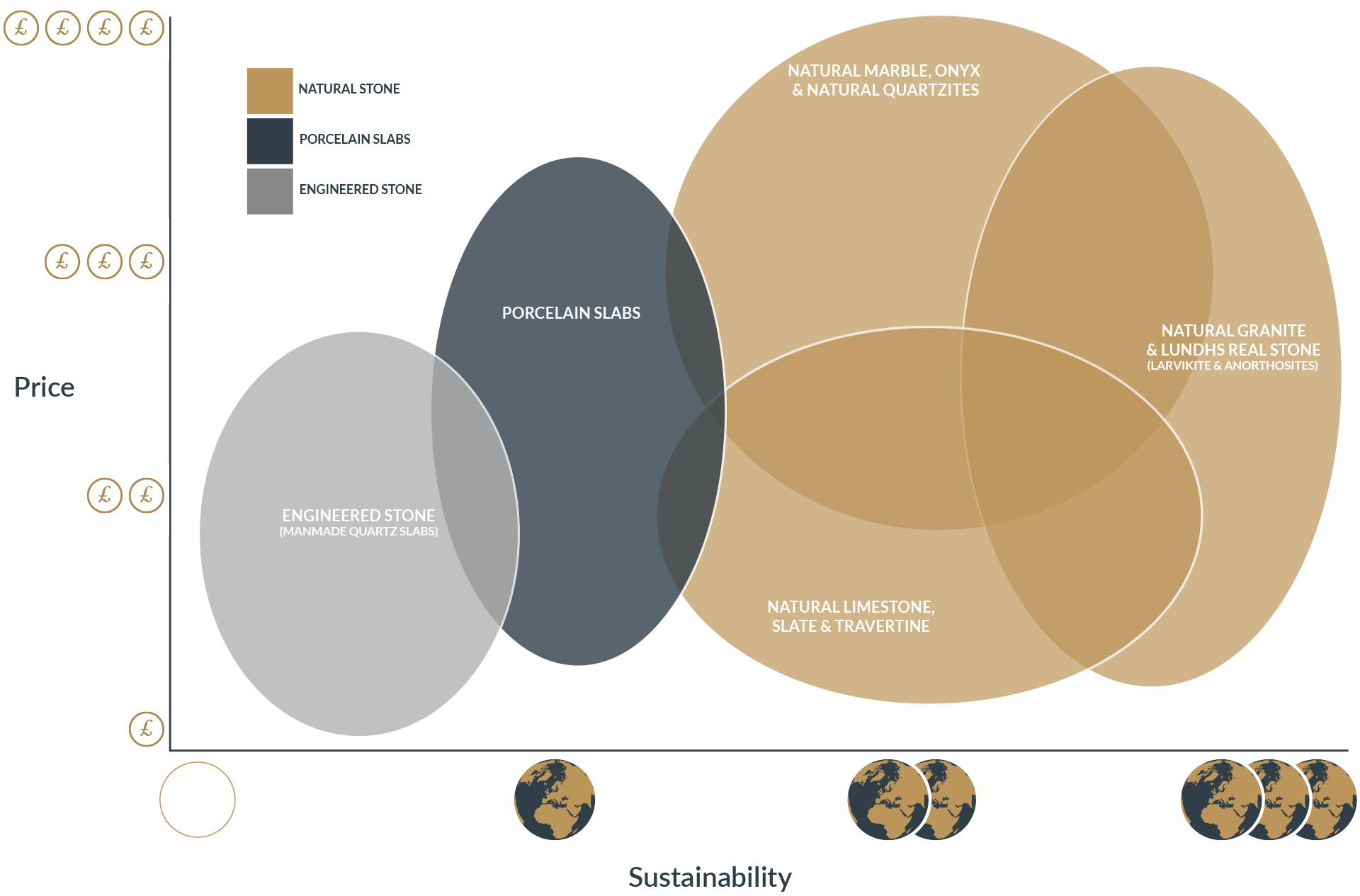

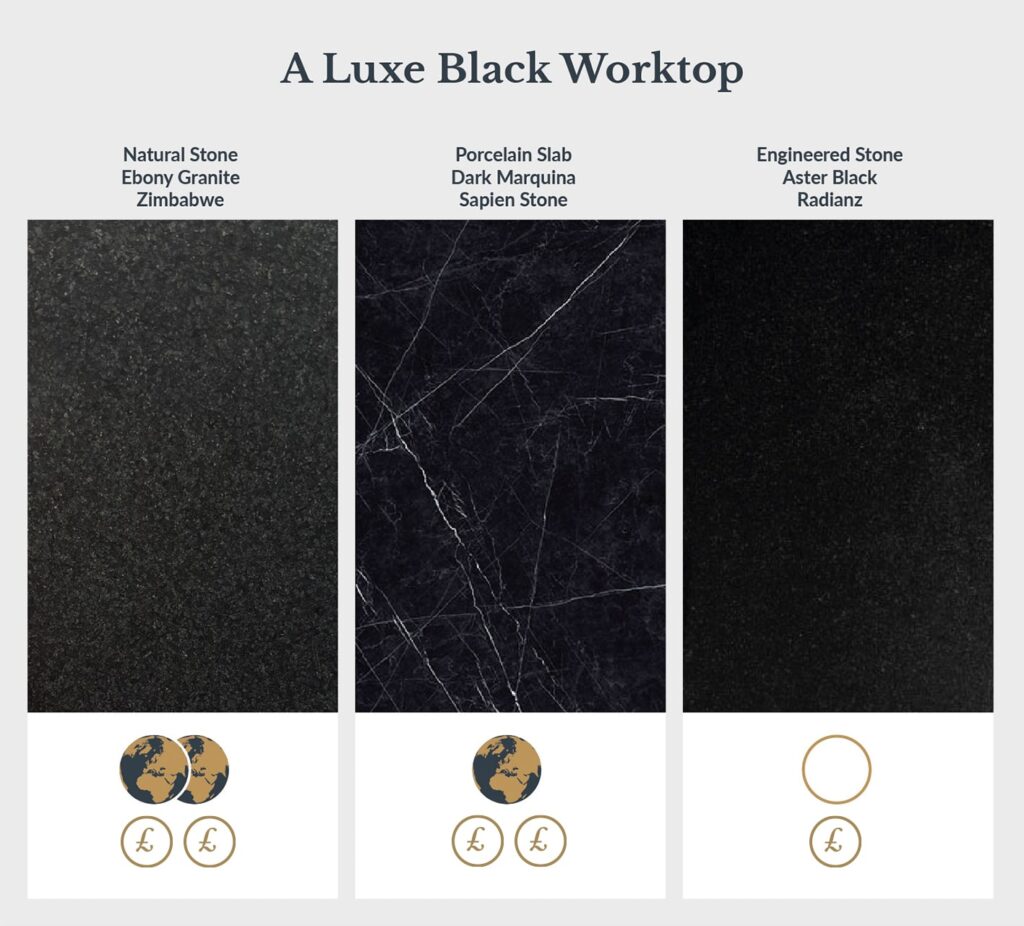

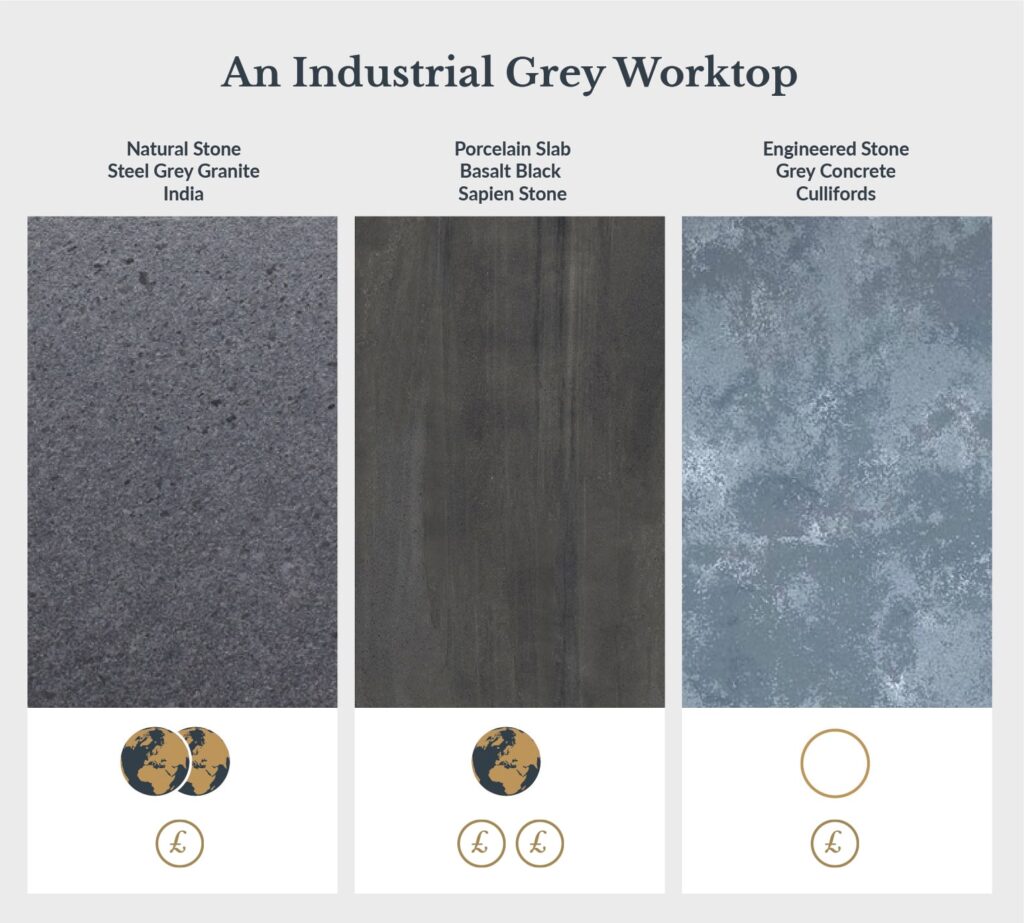

Stonecut Price & Sustainability Ratings

Sustainability Guide

Pricing Guide

Product Price / Sustainability Mapping

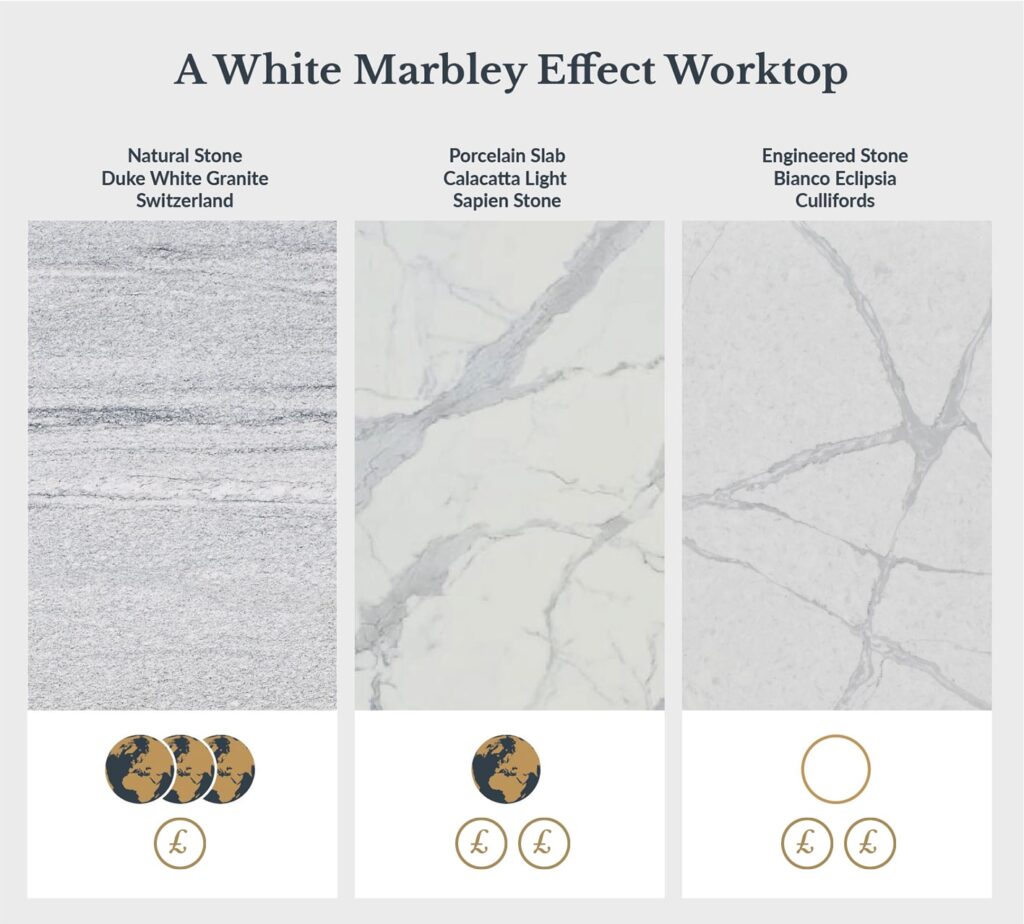

How To Use Our Sustainability & Pricing Guides

The Customer Wants...

Repairs & Restoration

Reuse & Recycle

Get in Touch

Please don’t hesitate to contact us with any enquiries—we’ll be happy to answer your questions.